Higher Standards

Lower Turnaround Times

When complexity increases, so does the need for confidence. That’s why, for over 60 years, Walbar Peabody has been delivering highly complex, high-temperature, hot section engine component repair and manufacturing services others can’t – fast.

Reliability

Responsiveness

Specialization

Experience

Exceeding Expectations

For the most complex repairs

Nondestructive Test & Inspection

As a NADCAP, Gold Standard certified operation, Walbar Peabody’s Nondestructive Test (NDT) capabilities enable continuous validation of top tier quality and reliability. With on-site Fluorescent Penetrant Inspection (PFI), Magnetic Particle Inspection (MPI) and Radiographic Inspection (X-Ray), Walbar Peabody complies with NADCAP – AC7114A Rev C, AC7114/1 Rev B and OEM requirements (GEAE-S-U10, Pratt & Whitney S-U2).

Nondestructive Test & Inspection

Coating & Plasma Spray

As a NADCAP, Gold Standard certified operation, Walbar Peabody performs a wide array of different coating operations, complying with a broad range of requirements: Chemical Vapor Deposition, complying with NADCAP AC7109/3 Rev B; Pack Process – Above Pack, complying with NADCAP AC7109/3; Pack Process – In Pack, complying with NADCAP AC7109/3; Slurry Process – Spray, complying with NADCAP AC7109/3. In addition to NADCAP standards, our coating processes comply with many OEM standards, such as : P&WC CPW-550, -537, -633, PWA77, PW SPOP 70-46-00 Plasma Spray, GEAE AP 70-49-00 Thermal Coatings, GE F50TF37 CL-B, GE F50TF68 CL-A & B, GE F50TF59 CL-C.

Coating & Plasma Spray

Vacuum Braze

As a NADCAP, Gold Standard certified operation, Walbar Peabody’s advanced braze techniques focus on nickel and cobalt based alloys, with experts onsite specializing in the brazing of details and wide gap braze repairs (complying with GEAE ADH, P&WC and limited Turbofix II specs). Our operation has a wide array of furnaces, enabling broad brazing capabilities, such as vacuum and controlled atmosphere furnace brazing, all of which comply with AMS 2675, while also complying with additional customer/OEM specification as applicable (GE Aerospace CC01 per P9TF1; P10TF1; M50T1; ANSI/AWS C3.6; ANSI/AWS C3.7; S-405)

Vacuum Braze

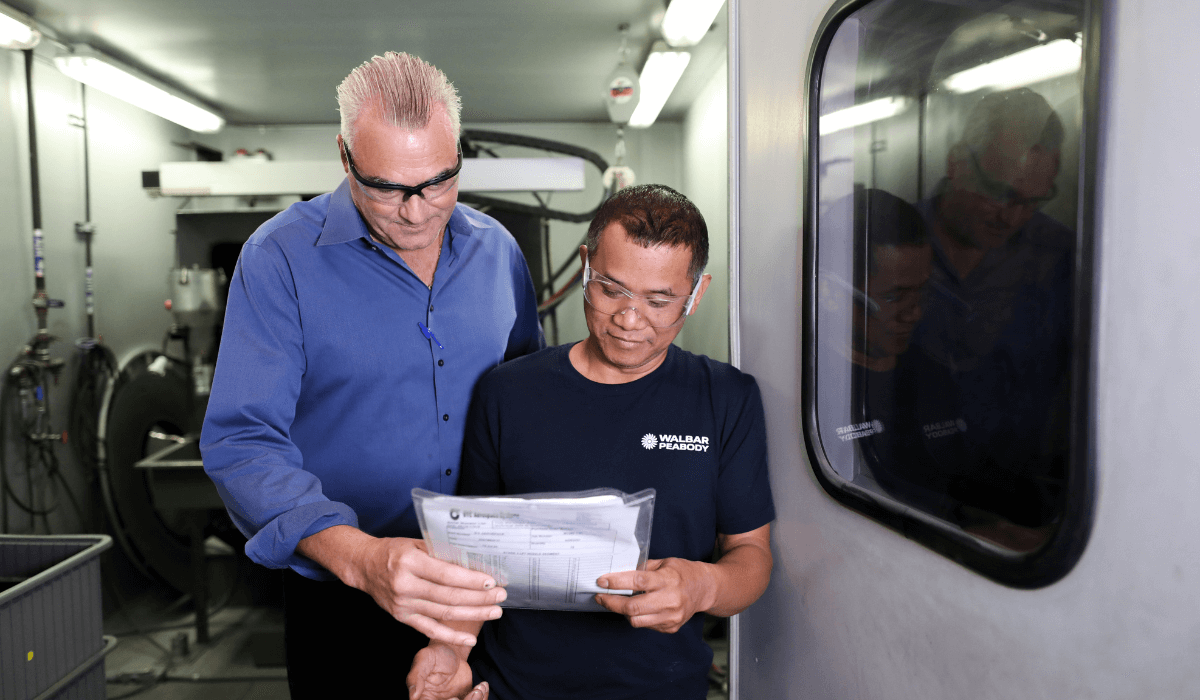

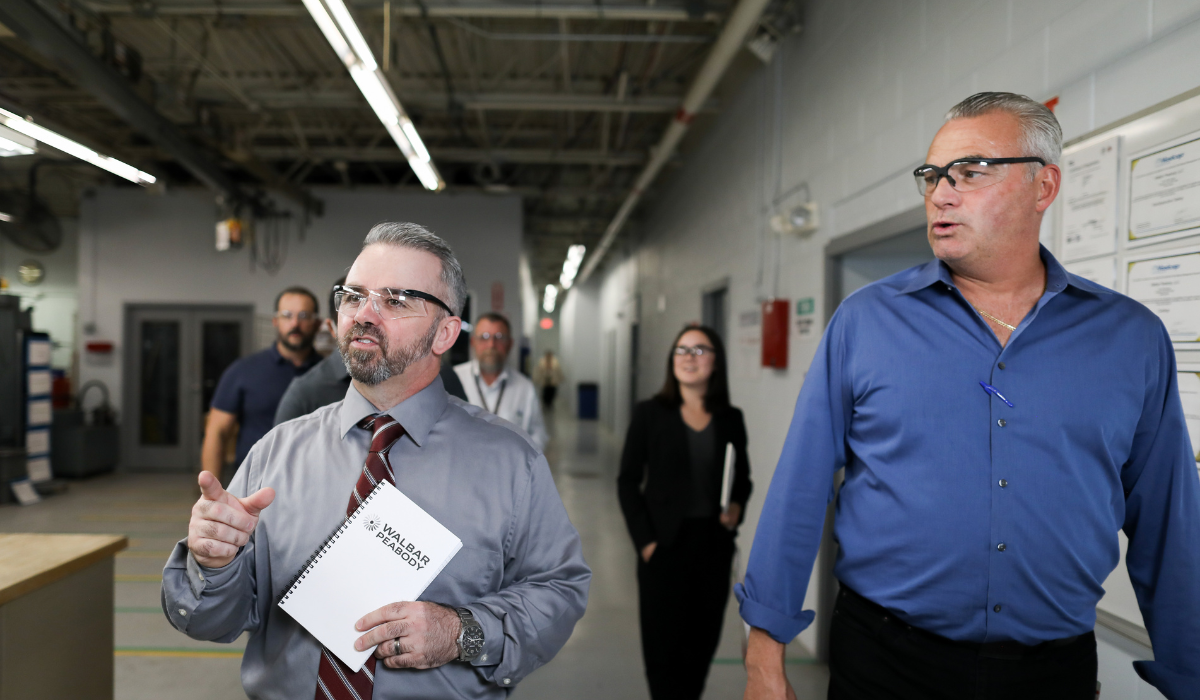

Unmatched Experience

Unexpected Access

Our way of doing business is to combine one-of-a-kind expertise with truthful, transparent, and frequent communication so you always know where you stand.

0

Shipped Orders

0

Delivered Units

0

Confident Customers Created

0.6 HRS

Average Turnaround Time