As 2024 has come to a close, the Walbar Peabody team reflects on our company’s hard work and accomplishments over the past year. While we’re excited for the year ahead, we believe every team needs to take a moment to celebrate their wins!

It was undoubtedly a year of growth, from making process improvements that have shortened turnaround times to leveling up our marketing and branding, leading to new prospects and opportunities. Discover what this means for our team, partners, and customers.

Joining the Collins Aerospace Portal

Perhaps one of the most exciting updates is that Walbar Peabody will soon be added to the Collins Aerospace portal! This will allow customers to find the part numbers and services that we offer.

When a customer has a part that’s being overhauled or coming out of an engine or tear-down, they’ll be able to go to the portal, search by the part number, and Walbar Peabody will come up as a maintenance repair overhaul (MRO) provider. This milestone will help grow our client base and promote the expansion of our capabilities.

Revamping Our Capabilities

Speaking of our capabilities, we also looked closely at our components and offerings in 2024. The engineering team revamped our capabilities and services, along with the entire product line that we service. Simply put, we overhauled what we do!

Additionally, we’ve focused on expanding product lines we are already substantiated for and broadening our capabilities within CF6. To that end, we’ve been exploring different repair techniques. For example, we were familiar with SWET weld but didn’t yet have the capability. Now, we are researching more capabilities like this for our current product lines, which in turn will help with business development.

Strengthening Internal Collaboration with RTX

Even better? We can share these expanded services with our customers and across RTX entities, including Intertrade, Pratt & Whitney, and Collins Aerospace. This means that if they have a customer who needs any of our specialized services, they can send them to Walbar Peabody for support.

Working with these entities internally has been another major milestone for us. We can now offer fellow RTX companies MRO and highly specialized services. We continue working with Collins Aerospace to meld our services across RTX.

Streamlining the PO Review Process

At Walbar Peabody, we’re passionate about process improvements. After all, they result in a better customer experience and higher quality.

Another area where we made significant strides is in our improved PO review process, which we made more efficient. While there used to be three departments involved in PO reviews, we’ve brought it down to only engineering. Previously, the process typically took about two to three days (in which the part was on hold waiting for everyone to perform their required PO reviews). Now, it is typically done in one day, making the induction process much more efficient and reducing cost and turnaround time.

We also created standard works on performing PO reviews, so there is no single-point failure. Since only engineering is conducting reviews now, our engineers are undergoing training to conduct effective peer reviews and know how to train others.

PO review involves in-house induction of parts before anything starts. We must ensure the paperwork is correct before we move ahead. Sometimes, we have to reach out to the customer to change something. We need expertise to know what to look for and ensure compliance. There is no room for error regarding PO review, so this is huge for quality and ensuring customer satisfaction!

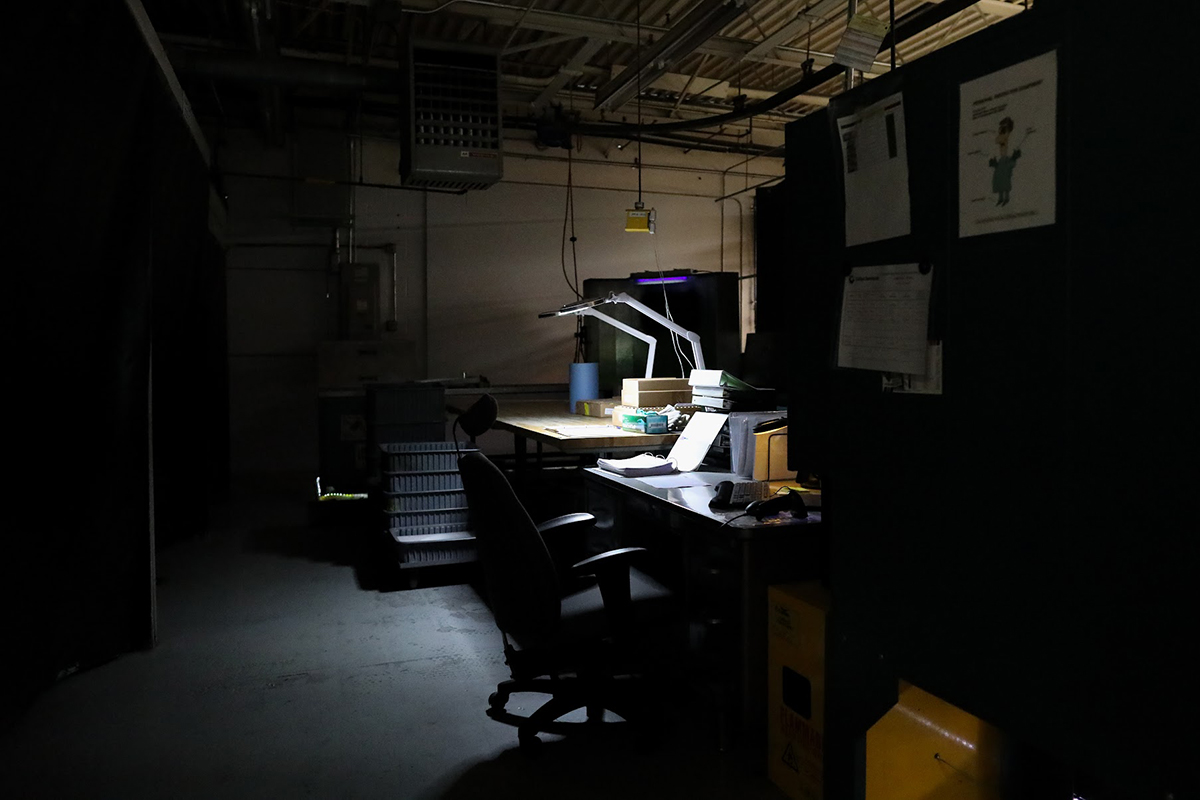

Elevating the Walbar Peabody Brand

Finally, Walbar Peabody partnered with Mill + Co. over the past year to take our marketing and branding efforts to new heights, including our facility’s look. We now have signage and collateral for trade shows and events and have been doing more marketing, meeting with more customers, and creating more brand awareness.

Our website, articles, and email strategies have led to more inquiries. In fact, these efforts opened our scope of work to not just aviation parts but other potential services to provide to customers. We’ve started receiving and exploring opportunities for anyone to utilize our specialized processes, such as fluoride ion cleaning (FIC) and brazing.

For example, a previous prospect looked at our site and learned that we provide FIC from one of our articles, but sent their parts elsewhere because we were an aviation company. However, they weren’t happy with their experience with the other company and returned to us.

Now, we’ve shifted our mentality and messaging to publicly share that we offer FIC not only for FAA components but also for first article products. This means we do the process, and they get a certificate of conformance (COC). A first article product is one that an engineer has developed for a purpose, and we apply this service.

Bottom line: One article on FIC brought in this potential work that could lead to our service expansion!

Positive Outlook for 2025

Walbar Peabody is primed for growth in 2025 thanks to our efforts and learning experiences last year. We’re thrilled about the potential opportunities ahead, especially as a team of people who love constant learning and improvement! And of course, so much of what we do centers on creating the best possible customer experience.

If you’re looking for an MRO partner who always strives for better, contact us today!