Walbar Peabody’s commitment to quality and efficiency begins the moment a customer’s order enters our system. But what happens to your components as they journey through our work-in-progress (WIP) flow management program?

The maintenance, repair, and overhaul (MRO) world can seem like a mystery, but we’re happy to share what goes on behind the scenes. In fact, we are all about transparency and collaboration and could likely talk about it all day! Don’t worry, we won’t—here’s a general breakdown of how repairs move through our streamlined process and WIP structure.

1. Order Induction

Once we receive your order, we promptly induct it into our system. The Customer Service team will record all necessary details and notify you if we need additional information. We’re thorough from the start to promote accurate and efficient processing.

2. Initial Inspection

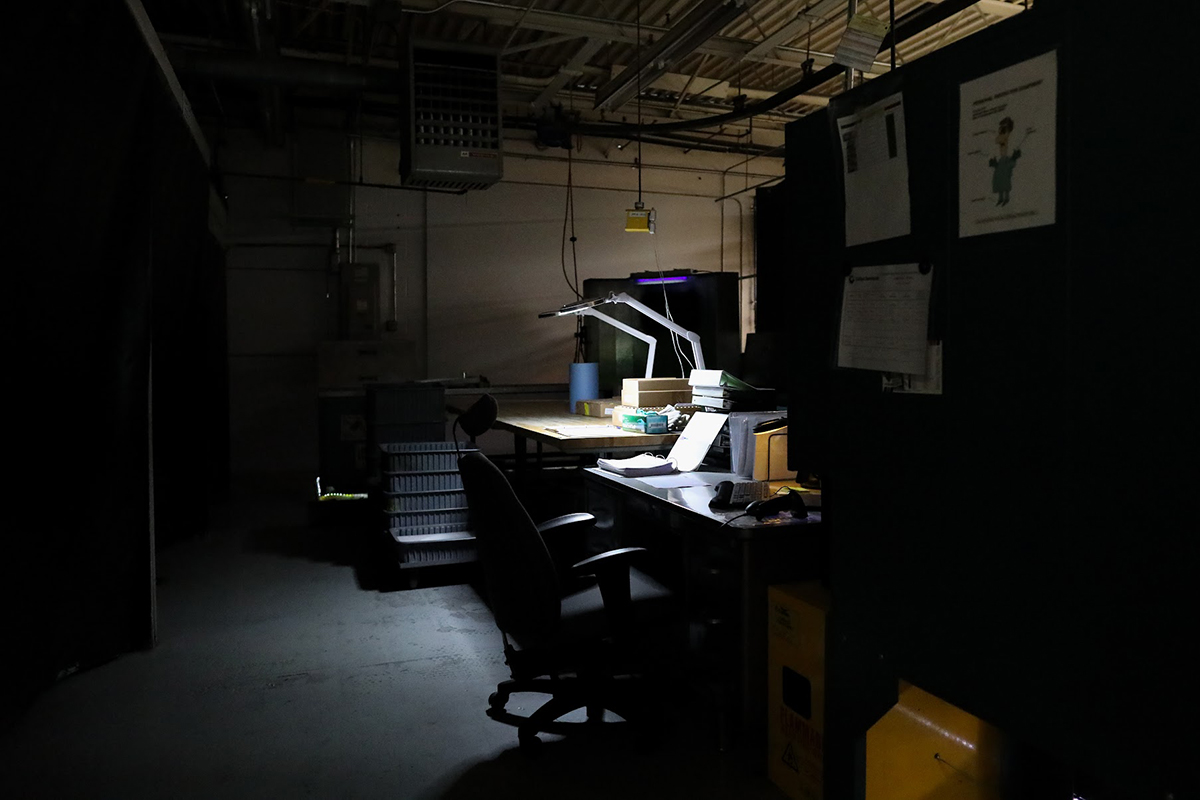

After induction, components are released to the floor, where our skilled engineers perform a thorough inspection. During this phase, we assess the condition of the parts to identify the required repair or overhaul work. Get a closer look at our intriguing floor process and a day in the life of our engineers.

3. Quote & Disposition

We provide a detailed quote after the inspection, including the cost and findings from our assessment. Transparent communication is key—if complications arise, such as the need for additional work, we reach out to discuss the situation and offer solutions. The same goes if parts are deemed unrepairable or undergo mid-process failure. However, we do everything possible to service components and provide options and recommendations when they’re not.

4. Collaborative Repairs

Repairs move seamlessly through our interconnected departments. Our Quality, Engineering, and Production teams work closely to ensure each repair meets rigorous requirements from the FAA and manufacturer. You’ll find no bottlenecks here—our emphasis on collaboration allows us to work efficiently and deliver the best results.

5. Work-in-Progress Monitoring

Our WIP structure provides real-time progress tracking throughout the life of every repair. We closely monitor turnaround times (TAT) and proactively update customers about any unexpected delays or issues. Your components will be handled with precision and care, whether a routine repair or an expedited order.

6. Final Quality Inspection

You already know that quality is at the heart of what we do—so of course, each repaired component undergoes a final round of quality checks before shipment. We review all documentation to verify that all processes have been followed properly throughout our extensive workflow. This step guarantees that your parts meet or exceed industry standards and are ready to perform at their best. With our intense quality control procedures, we aim to make everything we do as safe and mistake-proof as possible to save customers time and money.

7. Shipping & Tracking

Once repairs are complete, we ship your order and provide an air waybill (AWB) with tracking information. The AWB includes key details about your shipment, such as its description, flight details, handling instructions, and other terms and conditions of carriage.

The Walbar Peabody Difference

Our repair process is rooted in collaboration, transparency, and exceptional customer service. By eliminating silos and fostering teamwork, we can adapt quickly to the complex and time-sensitive demands of the MRO industry.

From receiving your order to the final delivery of your repaired components, Walbar Peabody is your partner every step of the way. Whether it’s maintaining open lines of communication, expediting urgent orders, or going the extra mile to find solutions, we’re here to support your success.

If you’re ready to experience unparalleled repair services for your hot section engine components, contact us today. We’ll get you off the ground—fast.